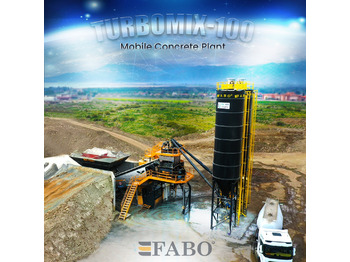

Plusmix 100 m³/hour MOBILE Concrete Plant - BETONNYY ZAVOD - CENTRALE A

Plusmix 100 m³/hour Mobile Concrete Batching Plant - BETONYY ZAVOD - CEN

Plusmix 60m³/Hour MOBILE Concrete Plant - BETONNYY ZAVOD

Plusmix 100m³/hour Stationary Concrete Plant -BETONYY ZAV

Plusmix MT30 : 30 m³/ hour MINI MOBILE Concrete Plant

Plusmix PLUS MT 120 MOBİLE CONCRETE PLANT PLUSMİX

Plusmix PLUSMİX MT120-TWN Double Chassis -:120m³/hour Mobile Concrete P

Plusmix 60m3/hour STATIONARY Concrete Batching Plant - BETONYY ZAVOD-CEN

PROMAX MOBILE CONCRETE BATCHING PLANT M100-TWN (100m3/h)

ELKON Mobile Master-100 LION Mobile Concrete Batching Plant

Pabrik beton baru Plusmix 100 m³/hour MOBILE Concrete Plant - BETONNYY ZAVOD - CENTRALE A

Published: 2th

Kami memiliki banyak penawaran serupa

Lihat apa yang ada di stok sekarang

Published: 2th

The seller didn't indicate the price

Do you want to know prices for the similar offers?

Lihat apa yang ada di stok sekarangCE certificated Concrete Plants 24/7 customer support and aftersales services FREE OF CHARGE ASSEMBLY & TRAINING. GENERAL TECHNICAL SPECIFICATIONS

Plant type: Mobile concrete plant with an Horizontal shaft mixer

Plant Capacity : 100m³ / hour compressed fresh concrete

Mixer Capacity : 2000 Liter (2m³ Compressed Concrete) Mixer Type : Single Shaft Mixer

Total Motor Power : 110 kw Standard Value. It may vary depending on the equipment.

Voltage / frequency : 380V / 50Hz Standard Value Electronical equipment : Siemens

Other equipment & accessories : Italian Automatic lubrification system (ILC : ITALIAN) Laptop (with software package), printer, uninterruptible power supply and SCADA software package, all control and monitoring processes, all kinds of reporting, failure notifications, etc. This process is done on the computer screen and with animation support. FOR MORE INFORMATION PLEASE CONTACT US NOW

MIXER GROUP

Main unit of the mobile concrete plant. All equipment is mounted on the trailer chassis and the system is made fully mobile. Compared to stationary concrete plant, mobile concrete plant has many advantages. To list the main ones;

- Low set up costs. There is no need for large foundation concrete bases for the installation of a mobile concrete plant. Only the basic concrete pedestal for the cement silo should be constructed. This way, set up costs are minimized.

- Easy set up and commissioning. While the installation of the stationary concrete plant lasts 10 to 15 days, the installation of the mobile plant lasts 2 days and 1 day for each welded type of cement silo installation and 3 days for the bolted type cement silo is enough.

- Easy maintenance and low maintenance costs. Since all equipment is compactly mounted on the trailer chassis, the mechanisms can be disassembled and maintained or replaced in a very short period of time.

PLUSMIX SINGLE SHAFT MIXER GENERAL SPECIFICATIONS

. Double-spiral arm design ensures obtaining desired homogeneous mixture in the shortest time.

Special GAMAK electrical motor is driven by 37*2 kW YILMAZ reducer.

Thanks to the spiral mixer arms which fully sweep the inner surface of the mixer, obtaining concrete at the desired quality is possible. There are 2 group mixers and 2 panel scrappers available as right helix and left helix. Liners are 14-16% manganese cast and palettes are produced from Ni-Hard4 cast material.

Fast and easy unloading.

Max. 110 mm sized aggregate mixing capacity.

In the event of a power failure, there is a quick coupling and lever on the unit to manually open the hydraulic discharge cover and the lid to unload the concrete mixture in the mixer.

Low operating and maintenance costs, fast and easy to use mixer shafts and seals.

Chain drive system, easy to service and maintenance.

The inner wear liner plates are easy to replace.

Operator faults are prevented by using ILC (Italian) Automatic centralized lubrication system. Bearings are lubricated with our time-controlled lubrication system to prevent hazards such as oil leaking or heating, winding.

Main Aggregate Bunker :

4 niches. Each niche with 15 m3 aggregate storing capacity. A total of 60 m3 capacity.

5 mm. Made of St-37 sheet metal.

Four pneumatic cylinders for dosage lid control, one for each niche.

A total of 2 electrıcal italian vibrators in aggregate bunker sand niches.

Aggregate Scale :

3.000 kg weighing capacity

5 mm. Made of St-37 sheet metal.

4 pcs. KELLY Load-Cell weighing cells.

The ability to digitally view weighing data in the control panel.

Mixer Feeding Band :

Band Width: 1.000 mm Length: 14.000 mm

15 kW. GAMAK electrical motor DISSAN reducer.

EP125, 4 layers of rubber covered, 10mm. thickness, manufactured according to TS542 standards.

Locked type motor coupling reducer is used to prevent line slip. The driving drum is covered with rubber

Water Scale :

Mounted on the mixer. 550 kg. water weighing capacity.

ø150 Italian electro pneumatically controlled dump valve under the water scale.

3 pcs. KELLY Load-Cell weighing cells.

Cement Scale:

Mounted on the mixer. 900 kg. weighing capacity.

ø300 Italian electro pneumatically controlled dump valve under cement scale.

3 pcs. KELLY Load-Cells.

Italian electrical vibrator.

Additive Dosage System :

Mounted on the mixer. 50 kg. weighing capacity.

1 pc. KELLY Load-Cell weighing cell.

Electro pneumatically controlled bottom dump valve.

Operator Cabin :

Made of 2 mm St-44 sheet metal, dimensions are 2400 mm x 2200 mm x 2200 mm.

Thermal insulation was made by using 40 mm glass wool between the sheet panels.

As an option, may be equipped with camera system to monitor aggregate bunker fill rate and color TV.

Air Compressor :

AK6000/500 AKKOMP

Motor Power = 7.5 HP.

(Dimensions 800 x 1800 x 1400)

Operating pressure 7-8 Bar. Air flow rate 860 litres/minute

550 litres air tank

Main Trailer Chassis :

Made of IPE 220 St-44 profile. 2" king Pin diameter.

Transportation dimensions are width: 2.980 mm; length: 18.620 mm; height: 4.010 mm.

Mounted on scissor double-axle. (290 mm x 290 mm x 2.000 mm)

4 tires on the double axle (2 right, 2 left) (385x65R 22,5)

All metal surfaces are sandblasted after welded manufacture and applied final coating after priming.

Trailer up-down level is adjustable with a 25 ton capacity mechanical jack

AUTOMATION SYSTEM

PLUSMİX brand concrete power plant automation systems are used in PLUSMIX concrete power plants. All system control is provided by Kartal or lion (display control panel ) designed by Turkish engineers. The PLC modules used in system control operate only as interfaces. The indicators used in weight measurement are high-tech and small-size, fast, responsive and accurate. The key materials used in the MCC control panel are SIEMENS brand. All control cables on the control panel are labeled on the ports. In this way, fault detection and monitoring can be done more easily.

Concrete production is completely automated through the computer. If necessary, the system can be interfered with using a mouse from the SCADA screen. The system in the SCADA program can be designed according to the characteristics and type of the official plant.

In addition to fast and reliable operation of the BETOSYSTEM SCADA program, it is also possible to access statistical and detailed production information. All reports made on the basis of the most preferred detailed production, prescription, customer, carrier and material can be obtained in detail from the computer screen or printer within the desired date range. In addition, if desired, the report can be designed with a custom reporting option. Our automation system guarantees accurate and accurate production as well as continuous and reliable operation with all high quality equipment.

SCADA PROGRAM

Computerized control system and control (SCADA) system

PLUSMİX; concrete production SCADA program ( Beto system ) is a process control program specially developed for concrete plants because the indicator, PLC, is a much faster communication between PC. The EAGLE indicator and control device, which is developed only for concrete plants, contains all the equipment required for the control of the plant. With its electronic buttons and Universal visualizations on Eagle, it provides ease of use to all operators around the world. All production is monitored visually through SCADA program, intervene if necessary, order, recipe, parameters, inventory acceptance, failure tracking and reporting details of the production can be taken. It is extremely easy to use and can be monitored remotely if desired. All the records of the production can be transferred to a specified PC continuously.

The seller didn't indicate the price

Do you want to know prices for the similar offers?

Lihat apa yang ada di stok sekarang